Structural Insulation

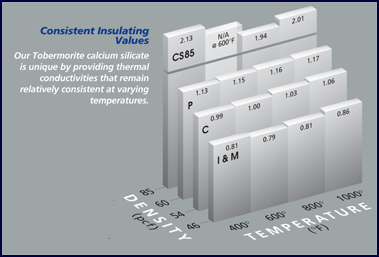

BNZ manufactures a variety of non-asbestos calcium silicate structural insulations that combine high strength and excellent thermal insulating characteristics for use in a variety of heat processing, fire protection, and electrical resistance applications. Our Tobermorite crystalline structure provides excellent thermal shock resistance as evidenced in its typical use as a direct contact board for non-ferrous metals and in fire training burn rooms. It is fire resistant to temperatures approaching 2000°F. The Tobermorite crystal is also unique by providing low thermal conductivities that remain relatively constant over a broad range of operating temperatures.

BNZ Materials manufactures, and is a worldwide supplier of a range of specialty industrial insulations and refractories for petrochemical, electrical, aluminum, steel, ovens, glass, furnace, ceramics, fire protection and other industries.

CS85

Marinite

These boards are heat treated formulations for use in conveying, containing and forming molten aluminum and other non-ferrous metals. Applications include holding furnace linings, tips for continuous casters, transition plates, rings, plugs, baffles, troughs, spouts, floats and filter boxes.

![]() PDF Data Sheet (Marinite A & C)

PDF Data Sheet (Marinite A & C)

SDS [![]() Marinite A] [Marinite C]

Marinite A] [Marinite C]

► Also View Board vs Castables

Marinite P, Marinite I & Marinite M

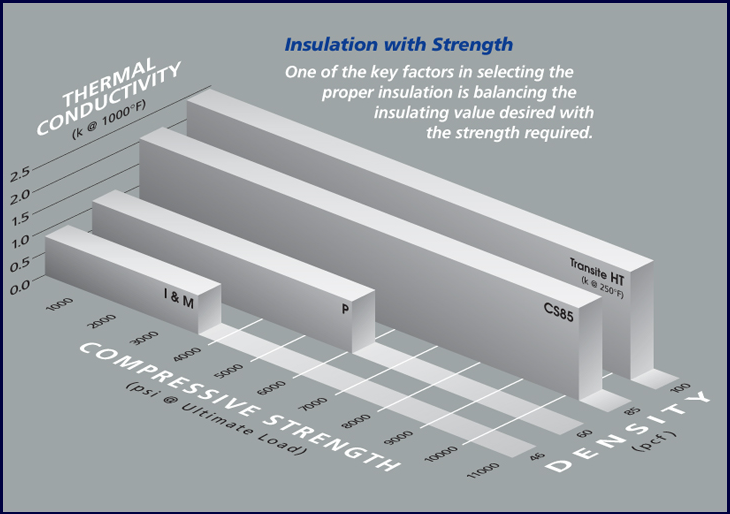

Oven dried formulations of BNZ boards are used in a variety of heat insulating processes, fire protection and machined parts. Selection is commonly based on a balance between strength and insulating qualities. Examples include oven walls and linings, soldering insulation, fire doors, fire training burn buildings, cable trays, personnel protection, and as USCG-approved insulation for marine ships and off-shore rigs. Back-up insulation applications include ladles, torpedo cars and tundishes in the iron and steel industry, lime and cement plant rotary kilns, and aluminum die cast holding furnaces.

PDF Data Sheets

![]() [Marinite P] [Marinite I] [Marinite M]

[Marinite P] [Marinite I] [Marinite M]

Transite

These non-asbestos, monolithic fiber cement industrial boards are used in environments up to 1000°F where high strength is the primary concern. These fiber cement boards are used in the foundry industry for flask liners, core, drying and carry plates, and induction furnace casings. Electrical applications include busbar supports, aluminum pot insulation, and electrode arm insulators.

Transite HT and Transite 1000 are also used as load bearing gasketing, spacers, supports, and machined parts for OEM applications.

PDF Data Sheets

![]() [Transite HT] [Transite 1000]

[Transite HT] [Transite 1000]

Various compositions and densities of BNZ Tobermorite calcium silicate structural insulations, along with a sampling of some typical applications, are listed below. Individual product data sheets and an extensive list of potential applications are available at your request.

Tobermorite calcium silicate provides excellent thermal shock resistance and stability compared to other forms of insulation, including other calcium silicates. Its low moisture content actually performs as a buffer to the crystal as intense heat attacks the insulation.

The insulation is also very stable at elevated temperatures witnessed by Marinite A with typical linear shrinkage of 0.1% at 1350°F, or CS85 with 0.3% linear shrinkage at 1800°F.

Consistently low thermal conductivity

BNZ’s Tobermorite crystalline structure provides thermal conductivities that you can rely on to be consistent throughout the operating temperatures the insulation will accommodate. This is particularly important in obtaining the energy savings desired.

For example, a unit can be designed with a thinner wall, while accommodating a wide range of temperatures. This means if a unit constructed of BNZ calcium silicate needs to have its processing heat increased beyond its designed operating temperature (i.e. due to increased production rates, or a higher temperature required for a new process), then you can rely on similar thermal conductivities to occur.

Calcium silicate insulation from BNZ combines high compressive and flexural strength with high insulating efficiency in a self-supporting board. Insulated housings (including ovens) can be built and insulated in one operation, eliminating the need for “through metal” supports. This reduces heat loss, prevents localized hot spots, provides uniform temperature control throughout the equipment and simplifies construction.

supports. This reduces heat loss, prevents localized hot spots, provides uniform temperature control throughout the equipment and simplifies construction.

These structural insulations are also often used in applications requiring minimal hot load deformation, such as heated platen presses, back-up insulation in rotary kilns and torpedo cars, and pre-insulated pipe supports.

Incombustible

Our structural insulations will not burn, providing excellent fire protection for personnel protection, cable trays, fire doors, and marine applications. In fact, Marinite was originally developed to isolate and prevent the spread of fires aboard ships.

All forms of BNZ calcium silicate insulations possess electrical insulating properties when dry. They are frequently used for low voltage applications that are accompanied with heat. Note that calcium silicate is hygroscopic, so its electrical resistance is reduced when it absorbs moisture.

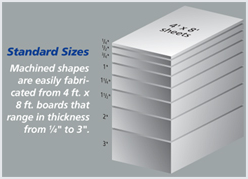

Our insulations are fabricated into precise shapes everyday by our worldwide network of fabricators/distributors who are well equipped to machine the most intricate parts. These insulations can also be machined with standard woodworking tools at slower speeds, utilizing carbide or diamond tipped tooling.

Calcium silicate is non-corroding and will not disintegrate even after prolonged immersion in water. It is well suited for excessive moisture conditions where metal may suffer from severe corrosion and other insulations can become mushy and dissolve. As an extra precaution in conditions with excessively high moisture and thermal cycling (including freeze-thaw), BNZ suggests the use of oligomeric siloxanes, sodium silicates (water glass), or acrylic latex to help prolong the longevity of the insulation.

Disclamer:

BNZ Materials warrants that its products are manufactured in accordance with its applicable material specifications and are free from defects in workmanship and materials using BNZ’s specifications as a standard. Every claim under this warranty shall be deemed waived unless in writing and received by BNZ within thirty (30) days of the date the defect was discovered and within one (1) year of the date of the shipment of the product.

[

[