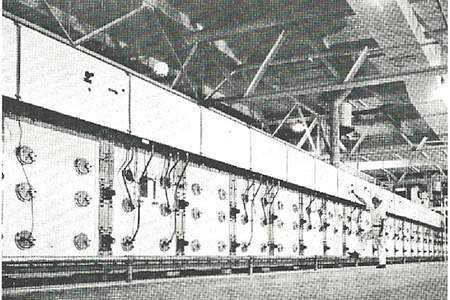

Marinite is multi-purpose material used in Marinite Baking Ovens that combines great structural strength with light weight and excellent thermal properties. It is fire proof and has a low thermal expansion coefficient. Marinite is completely non-corroding, and con be used either in its natural state or by adding enamel, stainless or aluminum sheets to the exposed surface areas of the side walls and top panels of the oven. From a report presented by Annual Training Conference “Having decided upon the size of oven required, and the amount of baked product required, the next most logical topic to investigate is oven construction and type of insulation used. This is very important to the oven builder. as well as the operator. as both ore concerned with the cost of the unit, sturdiness of construction and efficiency. Figure 1 Figure 2 Two gas-fired band ovens, for baking crackers and cookies, stand side by side. The same dough is fed to both, machinery merely being moved from one to the other. Denver Billerica Nashua ZelienopleMarinite Baking Ovens

Thomas R. Lugar

Vice President,

Thomas L. Green & Company, Inc.

Indianapolis, Indiana

Biscuit Bakers Institute.

“Basically, there ore two

types of insulation used, having token tor granted that the frames and sup porting members of the oven body ore made of suitable steels properly designed to support the

various loads. These two types of insulation ore Fiber Glass and Marinite. For purposes of illustration. I would like to refer to Figures

1 and 2.

“Figure 1 illustrates a Thomas L. Green Steel Oven in which Fiber Glass is used as the insulating material. Fiber Glass is a

“Marinite combines great structural strength with light weight and excellent thermal properties. It is fire proof and has a low thermal expansion coefficient. Marinite is completely non-corroding, and con be used either in its natural state or by adding enamel, stainless or aluminum sheets to the exposed surface areas of the side walls and top panels of the oven.

In addition to the foregoing, Mr. Lugar furnished the following performance comparison between Marinite and insulated metal panels:

Performance Comparison: Marinite vs. Insulated Metal Panels

Marinite Oven

Insulated Metal

Panel Oven

Oven Details

Insulation Thickness

3″ Marinite

8¼” Mineral Wood

Inside Dimensions

Same inside dimension in both ovens

Width of Band

38″

38″

Effective Baking Width

36″

36″

Length of Oven

100′

200′

Product – Oatmeal Raisin Cookies:

Baking Time

6 min.

9 min.

Weight of

Product Baked

1285 lb/hr

1755 lb/hr

Fuel (Propane)

Consumed

12 gal/hr

18 gal/hr

Weight of Product

Baked per Gallon of

Fuel Consumed

107 lb/gal

97.5 lb/gal

Quality

Excellent Texture;

Uniform BakeHard Texture;

Imperfect Bake

Advantages of Marinite Indicated by the Performance Comparison:

fuel.

2. Better than 33% less baking time.

3. Shorter oven required, occupying less space. While the insulated sheet metal oven has a 37% greater rate of production,it is 1000/o longer. For equal production rates, the Marinite oven would be almost one-third (32%) shorter or, conversely,the insulated

4. Produces baked food of superior quality

Warranty

Limitation of Liability

BNZ within thirty (30) days

of the date the defect was discovered and within one (1) year of the date of the shipment of the product.

BNZ within thirty (30) days

of the date the defect was discovered and within one (1) year of the date of the shipment of the product.

of BNZ’s liability shall be the resupply of a like quantity of non-defective product and that BNZ shall have no such liability except where the damage or claim results solely from breach of BNZ’s warranty.

OTHER DAMAGES FOR ANY ALLEGED NEGLIGENCE, BREACH OF WARRANTY. STRICT LIABILITY. OR ANY OTHER THEORY. OTHER THAN THE LIMITED LIABILITY SET FORTH ABOVE.1-1,53

BNZ Materials, Inc.

Corporate Headquarters

6901 South Pierce Street

Suite 260

Littleton. CO 80123

Phone: (303) 978-1199

Fax: (303)978-0308Marinite Plant Location

High Street

Iron Hourse Park

North Billerica, MA 01862

Phone: (508)663-3401

Fax: (508)663-2735Other Plant Locations:

40 Bridge Street

Nashua, NH 03060

Phone: (603)883-3361

Fax: (603)889-8935

Front Street

P.O. Box 190

Zelienople, PA 16063

Phone: (412)452-8650

Fax: (412)452-1346

Marinite Baking OvensBNZ Materials2020-02-25T00:06:48+00:00

The following is an excerpt from a report on “Ovens Burners-Bands” presented by Mr. Thomas R. Lugar, Vice President, Thomas L. Green & Company, Inc., at an annual training conference of the Biscuit Bakers Institute.

multi-purpose material for a wide range of industrial applications requiring a resilient.lightweight, inorganic insulation for thermal control. This oven is insulated with this high temperature insulation in a thickness of six inches. and is also equipped with refractory above and below the band in the baking chamber for the purpose of producing a solid heat. Both outside walls of the oven are removable panel sections, assembled complete with both inner and outer sheets, burner port openings. and insulation assembled complete. These removable sections ore held in place by clamping

strips and ore exact duplicates as to size and design…Fiber Glass is an excellent insulating material,with an extremely low thermal conductivity factor. In this type of oven.however. whether it be ours or another manufacturer’s, there still exists a large amount of ‘through metal’ which tends to increase heat losses to the extent that the benefits resulting from the lower conductivity factor of the insulation ore. to a large degree, nullified. By ‘through metal’ I mean metal which extends from inner to outer wall.top or bottom surface, and which provides on easy path for heat to escape.

“Figure 2 illustrates a Thomas L. Green Marinite Oven. Since the term ‘ Marinite ‘ may be unfamiliar to some of you, I would like to explain a little about it, since it is now being used in many ovens of different manufacturers in the baking industry today. “Marinite is an insulating sheet material composed of hydrothermally-produced calcium silicate and reinforcing agents. Because it is both a structural and an insulating material. it otters major economic advantages in the construction of ovens requiring a housing tor retention and control of heat. Marinite is one of the few insulation available that can be erected without the metal sheathing necessary when mineral-fiber type or similar insulating materials ore employed.

“Naturally, there are many published charts and specification sheets available on the properties of Marinite which I would be happy to send to any of you who are particularly interested in this type of data. Generally speaking, however, we have found this type of insulation in the construction of our ovens to provide a more uniform temperature control in the over, considerably less maintenance, and greater ease in the erection of the entire unit. Especially in plants where a variety of different products is being baked; I believe we will see a much greater use of Marinite as an insulation. In addition, the requirements for greater flexibility of

control will tend to reduce to a minimum the use of refractory material which tends to store heat and will lead to a greater emphasis on convection as the mode of heat transmission in the baking chamber.

1. Economical in fuel usage. Almost 100/o more cookies were baked with the same amount of

sheet metal oven would be practically one-half (47%) longer. Thus the total cost of the Marinite oven would be lower even if it happened to cost up to 47% more per linear foot. Conversely, the total cost of the insulated sheet metal oven would be higher unless it happened to cost at least 32% less per linear foot. None of this takes into account the 9% of fuel savings of the Marinite oven and its more economical use of space.

BNZ Materials warrants that its products are manufactured in accordance with its applicable material specifications and are free from defects in workman ship and materials using BNZ’s specifications as a standard. Every claim under this warranty shall be deemed waived unless in writing and received by

BNZ Materials warrants that its products are manufactured in accordance with its applicable material specifications and are free from defects in workman ship and materials using BNZ’s specifications as a standard. Every claim under this warranty shall be deemed waived unless in writing and received by

It is expressly understood and agreed that the limit

IT IS ALSO AGREED THAT BNZ SHALL NOT BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL. OR